Energy performance in process manufacturing industry

An essential but profitable investment with Energy Management System (EMS)

The year 2022 has been marked by tensions on energy supply (oil, gas, electricity). At the same time, new measures are being implemented to force players to reduce their CO2 emissions, including taxes on fossil fuels and CO2 emissions. Some of the causes of these tensions may be temporary, but most are structural and will persist.

This is not the first time we have been confronted with a surge in energy prices. Each time it has happened in history, it has been an opportunity for the industry to reinvent itself to meet the challenge.

What are the different aspects behind “energy performance”?

Energy performance can and should be seen as a systemic approach. The systemic approach is necessary because the different levers that can be activated are interdependent.

“Energy performance can and should be seen as a systemic approach.”

The following levers can be used to improve overall energy performance:

- Energy efficiency: reducing the energy required per unit of production. This reduces the energy cost by reducing the volumes used.

- Carbon intensity reduction: replacing the energy used with low carbon energy. This reduces the cost of CO2 emissions depending on local regulations and taxes.

- Energy flexibility: adapting its energy use to market conditions (energy mix, level of consumption…) to optimise the purchase price. This will reduce the unit price of the energy used.

How to implement “energy performance” approaches in industry?

Firstly, as a systemic approach is required, it is necessary to make a diagnosis of the different uses in the plant, for each energy. Assess for each use whether:

- It can be avoided or reduced (by assessing whether it is really necessary, by implementing methodologies such as the Pinch method to use energy from other fluids in the process…).

- It can be optimised (by finding the best operating conditions, etc.).

- The energy used can be substituted by another, possibly with a lower CO2 footprint (dual-energy boilers or furnaces capable of using electricity or gas, etc.).

- It is flexible and controllable (i.e. it is possible to modify the energy consumption of the process on demand for a certain period of time without strong impact on the process).

On this basis, assess the investment needed to achieve each objective and the expected gain. At this stage, it is recommended to build scenarios with different assumptions (energy prices, carbon taxes…) to test the sensitivity and risk of each investment. The value of each investment can be assessed from both an economic and an environmental point of view.

In parallel, appropriate performance indicators (KPIs) should be implemented to monitor the effectiveness of each action and ensure that economic and environmental objectives are met. Everything can be managed in an energy management system (EMS)

Data, a key lever to “energy performance” in industry

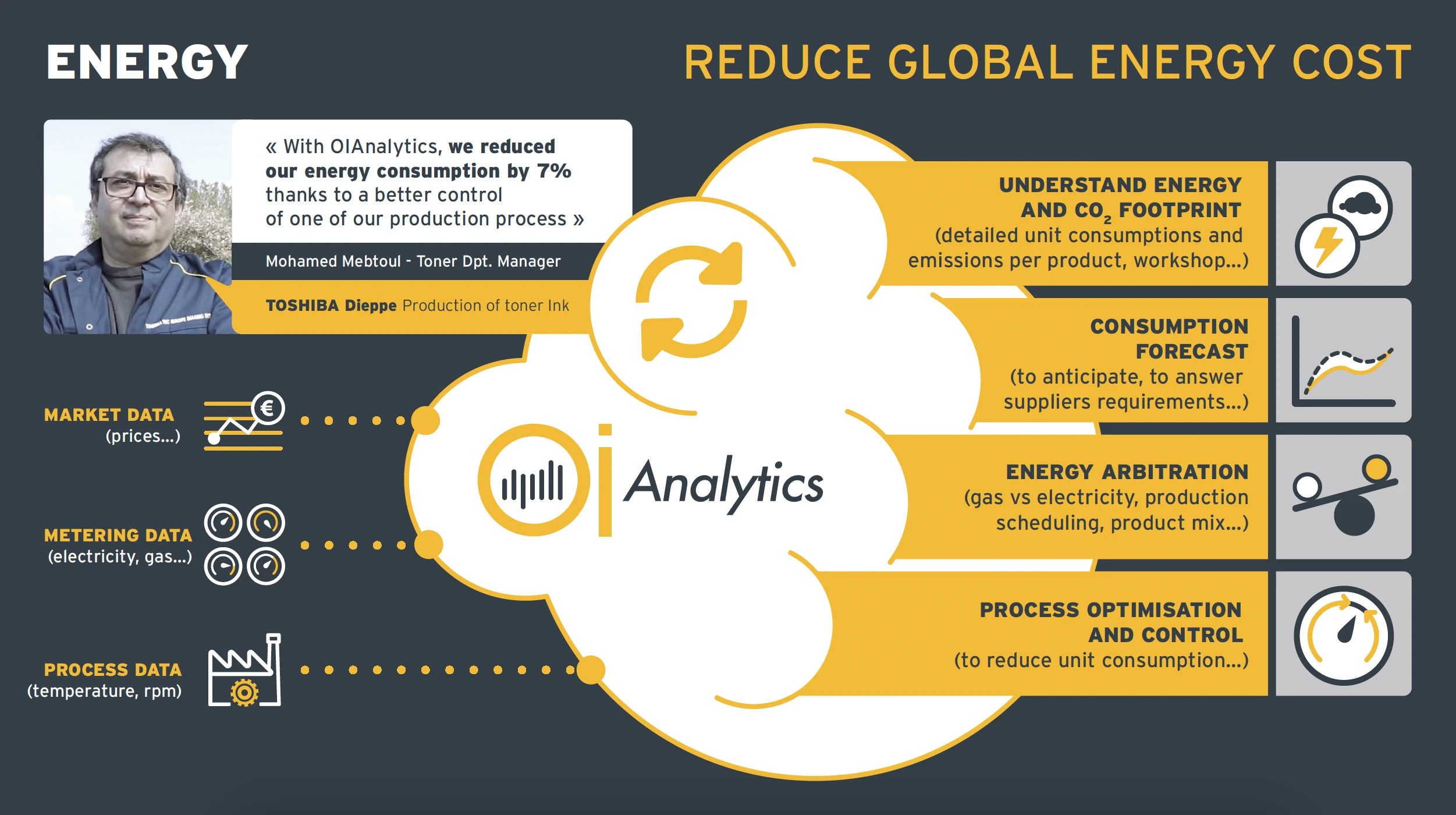

Data are essential at every stage of the approach:

- During the Diagnostic phase to determine the actions to be taken and to evaluate their feasibility.

- To implement the actions. In case of process modification investment, to design the process modification. In case of optimisation, to find the best operating condition based on past historical data and implement proper process control. In case of flexibility implementation, to provide operational teams with the proper real-time and forecast information to do the best arbitrations.

- All along, to build and monitor all KPIs to ensure that actions are implemented and effective.

Energy performance will be a game changer for many industrials. Only those who are able to tackle the issue in a timely manner will remain competitive in their market. A good combination of expertise, process re-engineering and data-driven decisions and controls will be needed.